PRODUCT CENTER

Inspect and prepare the subgrade → Manually lay the geogrid → Overlap, bind, and secure → Spread the upper layer of subsoil → Compaction → Inspection.

Precautions for Geogrid Installation:

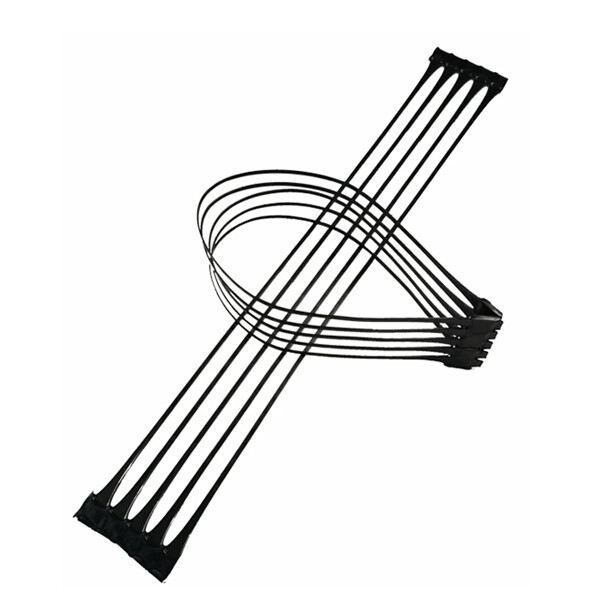

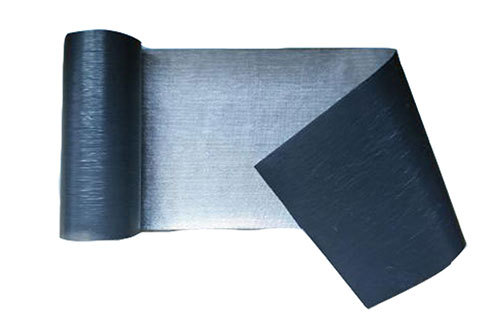

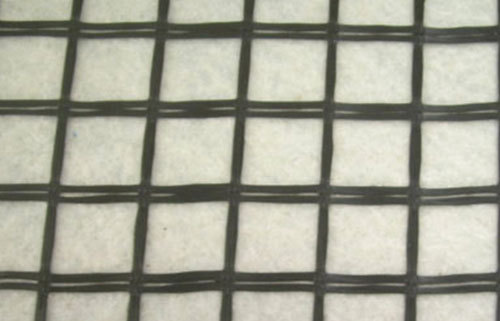

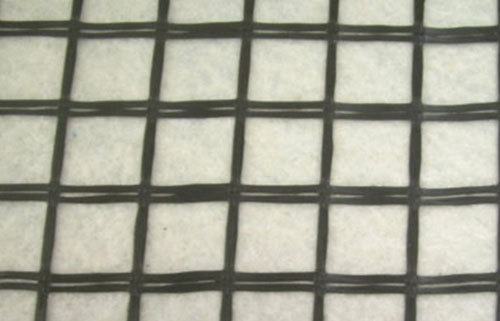

(1) The geogrid should be laid on a leveled subgrade according to the designed width. The fill material above and below should be free of debris that could damage the geogrid. During installation, the direction of high strength should be oriented perpendicular to the embankment axis. The geogrid should be laid horizontally, stretched taut, and kept smooth to avoid wrinkling, twisting, or sagging. Longitudinal splicing should be done using the overlap method with a minimum overlap width of 20 cm.

(2) After the geogrid is laid, the upper fill should be manually spread and compacted in a timely manner to avoid prolonged exposure to sunlight. Machinery should then be used for transporting, leveling, and compacting the material. Spreading and compaction should proceed from both ends toward the center, ensuring that the compaction meets standard requirements.

(3) All construction vehicles and machinery are strictly prohibited from driving or parking on the laid geogrid. The quality of the geogrid should be continuously monitored during construction. Any damage such as folding, puncturing, or tearing should be repaired or replaced based on the severity.

Geogrid Construction Method:

(1) First, accurately mark the embankment slope lines. To ensure the width of the subgrade, extend 0.5 m on each side. Level the exposed subgrade soil and compact it with a 25T vibratory roller in static mode twice, followed by compaction with a 50T vibratory roller four times. Manually level any uneven areas.

(2) Spread a 0.3 m thick layer of medium (coarse) sand. After manual leveling assisted by machinery, compact it with a 25T vibratory roller in static mode twice.

(3) Lay the geogrid. The base surface should be flat and compacted. The geogrid should be laid flat and straight without overlapping, bending, or twisting. Adjacent geogrid sheets should overlap by 0.2 m, and the overlapping sections should be connected crosswise at 1 m intervals along the transverse direction of the subgrade using No. 8 iron wires. Additionally, secure the geogrid to the ground at 1.5-2 m intervals using U-shaped stakes.

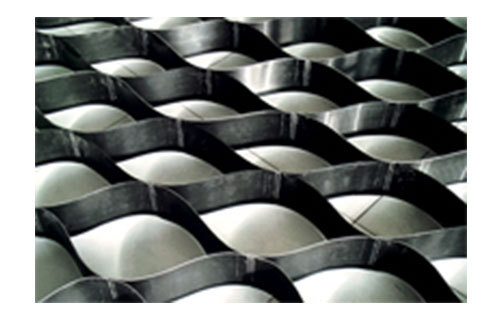

(4) After the first layer of geogrid is laid, begin spreading the second layer of 0.2 m thick medium (coarse) sand. The method involves transporting sand to the site via truck and unloading it on one side of the subgrade. A bulldozer is then used to spread the sand forward. First, fill the two sides of the subgrade within a 2 m range to a thickness of 0.1 m. Then, fold the first layer of geogrid back and fill another 0.1 m of medium (coarse) sand. Avoid filling from the sides toward the center or allowing machinery to operate on the geogrid without the sand fill. This ensures the geogrid remains flat, without bulging or wrinkling. After leveling the second layer of medium (coarse) sand, conduct elevation checks to ensure uniform thickness. Once leveled, compact it with a 25T vibratory roller in static mode twice.

(5) The construction method for the second layer of geogrid is the same as for the first layer. Finally, spread a 0.3 m layer of medium (coarse) sand using the same method as the first layer. Compact it with a 25T roller in static mode twice. This completes the reinforcement of the subgrade base.

(6) After compacting the third layer of medium (coarse) sand, lay two sheets of geogrid along both sides of the slope in the longitudinal direction of the route, with a 0.16 m overlap, and connect them using the same method. Then, proceed with earthwork operations. For slope protection using geogrid, the installation boundaries must be surveyed for each layer, ensuring that the geogrid is embedded 0.10 m into the slope after trimming.

(7) For slope geogrid installation, every two layers of fill (i.e., at a thickness of 0.8 m), a layer of geogrid should be laid on both sides simultaneously. Repeat this process until reaching below the surface soil of the shoulder.

(8) After the subgrade is filled, promptly trim the slopes and protect the toe of the slope with dry-laid stone pitching. In addition to widening each side of the subgrade by 0.3 m, allow for a 1.5% settlement reserve.

Product

Contact Us

Contact Person: Chen Fan

Phone: +8615666086733

Email: GangCaiDaWang@gmail.com

Address: Anlinzhan Industrial Park, Feicheng City, Tai'an City, Shandong Province

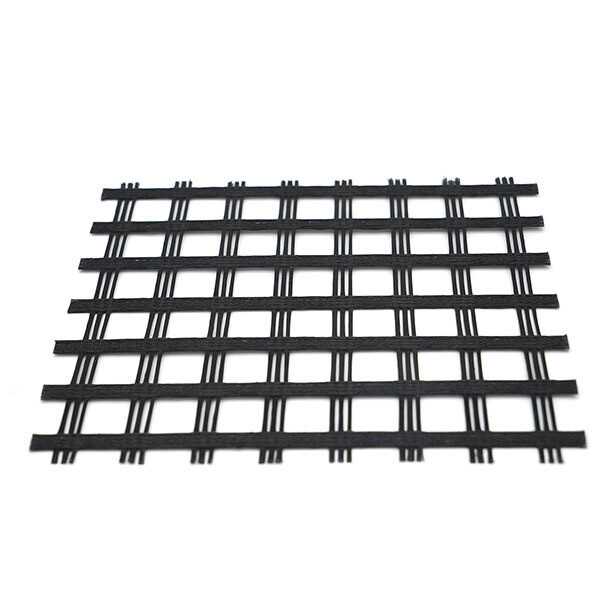

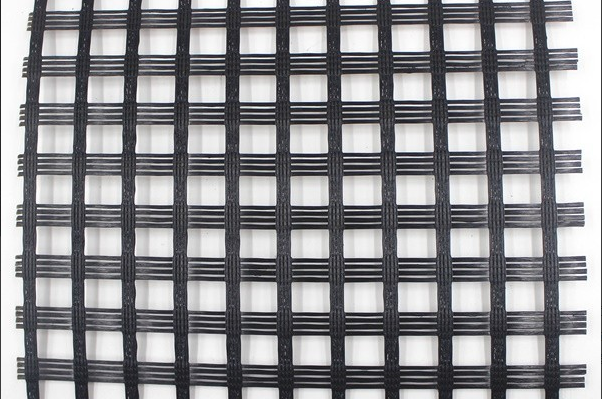

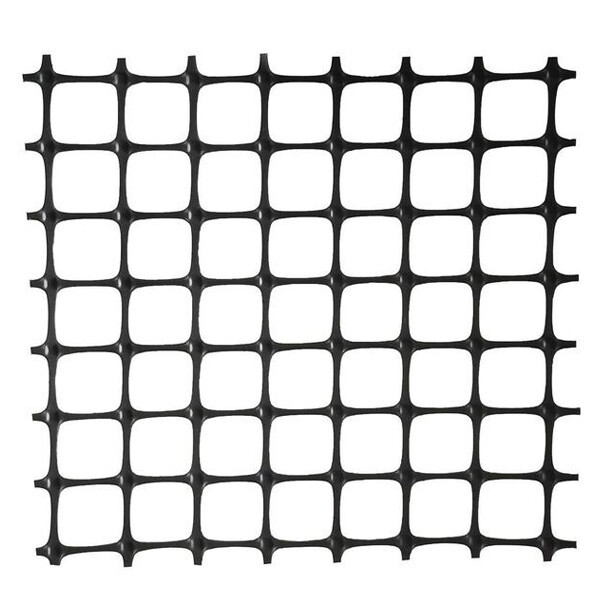

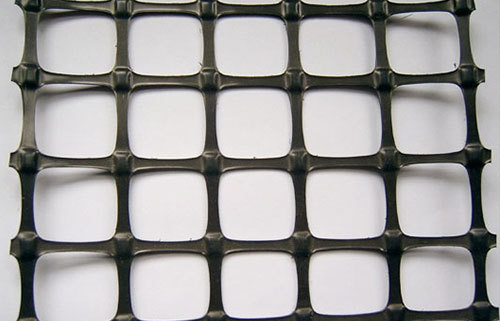

Product Display

Online Message