PRODUCT CENTER

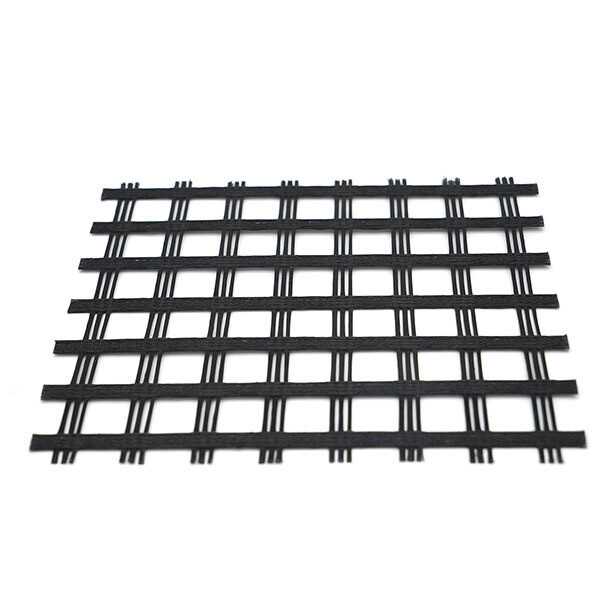

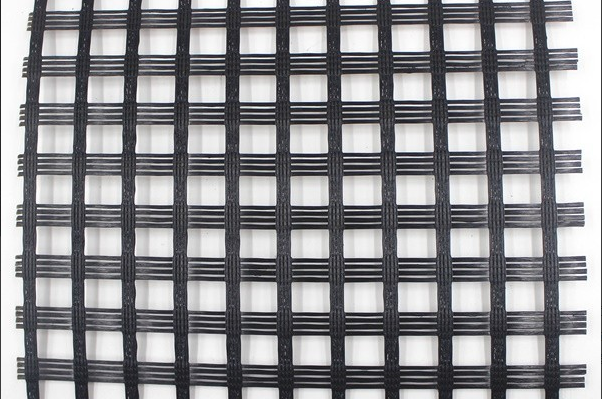

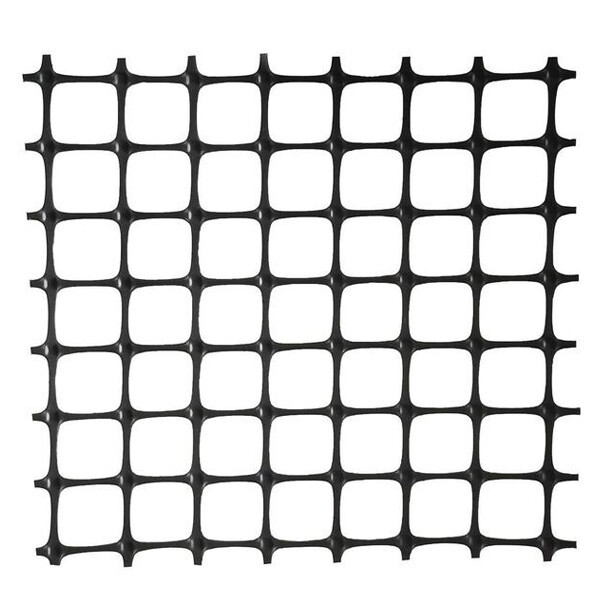

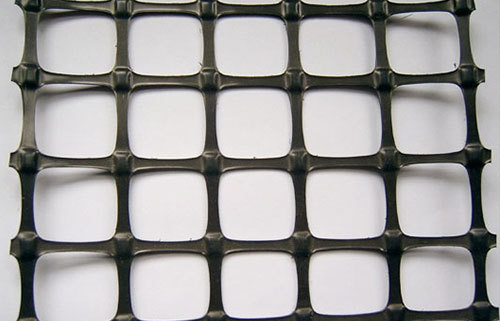

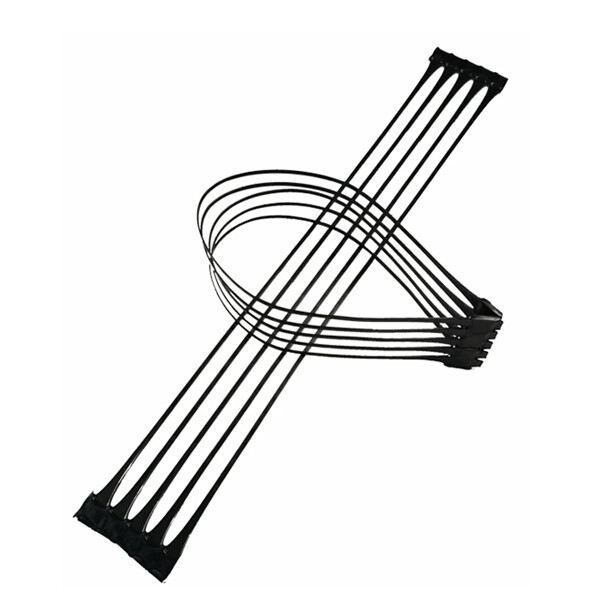

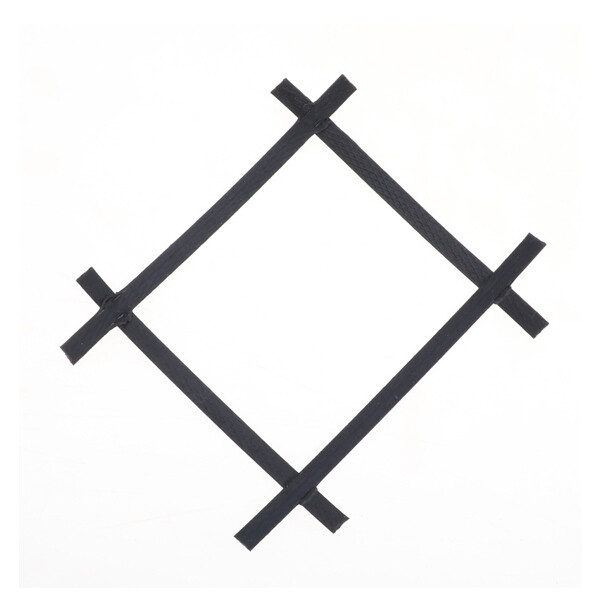

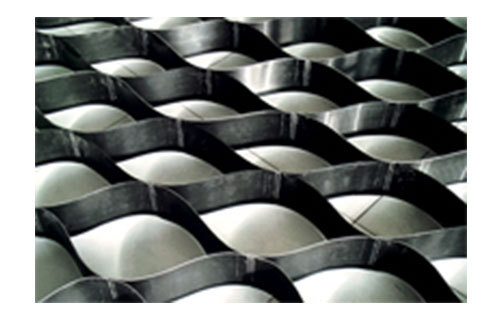

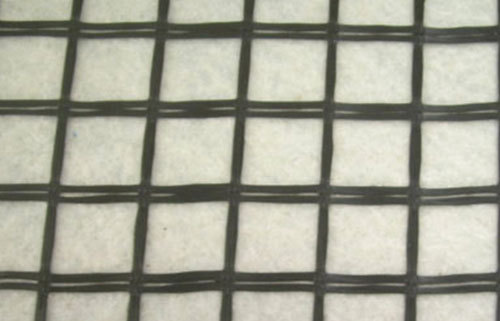

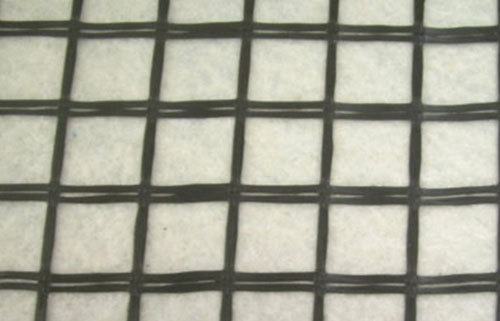

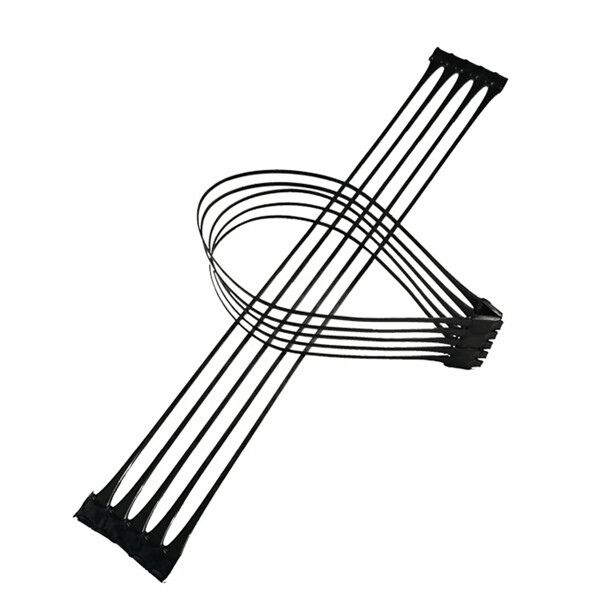

Unidirectional Geogrid is a high-strength geosynthetic material primarily made from polymer materials,with the addition of anti-UV and anti-aging agents.It is manufactured through a unidirectional stretching process that realigns the originally disordered chain molecules into a linear orientation.The process involves extruding and pressing into thin sheets,punching regular mesh holes,and then stretching longitudinally.This results in a high-strength geotechnical material with a uniformly distributed,high-node-strength,long-oval网状 monolithic structure.This structure exhibits exceptionally high tensile strength and tensile modulus,with a tensile strength ranging from 100 to 200 MPa,接近 the level of mild steel and far superior to traditional or existing reinforcement materials.Particularly,the company's products offer ultra-international-standard high early-stage (elongation at 2%–5%) tensile strength and tensile modulus,providing an ideal force-bearing and diffusion连锁 system for soil.The product boasts high tensile strength (>150 MPa) and adaptability to various soil types,making it widely used as a reinforcement material.Applications:

Unidirectional plastic geogrid is a high-strength structural material suitable for subgrade enhancement in highways,municipal roads,railways,airport runways,etc.Ideal for embankment reinforcement along rivers,lakes,and seas.Suitable for fencing in orchards,vegetable gardens,livestock enclosures,and other land uses,offering safety,convenience,ease of assembly and disassembly,and an aesthetically pleasing appearance.Applicable for reinforced soil retaining walls in highways,municipal roads,railways,airport runways,and river or coastal areas.Specifications and Performance Table of Unidirectional Plastic Geogrid GB/T17689-1999:

Product Specification TGDG25 TGDG35 TGDG50 TGDG80 TGDG110 TGDG130 TGDG180 TGDG260

Tensile Force per Meter at Yield,KN/m ≥ 25 35 50 80 110 130 180 260

Elongation at Yield,% ≤ 12 12 12 12 12 12 12 12

Tensile Force at 2% Elongation,KN/m ≥ 6 9 10 23 30 39 60 98

Tensile Force at 5% Elongation,KN/m ≥ 12 18 25 44 60 77 107 142

Creep Limit Strength,KN/m ≥ 11 15 21 30.2 41 49 64.8 102.5

■ Product Applications

Unidirectional geogrid is a high-strength geosynthetic material widely used in embankments,tunnels,docks,highways,railways,construction,and other fields.Product Features:

High unidirectional tensile strength,excellent creep resistance,and stable chemical properties.High friction coefficient with sand and gravel.Application Scope:

Mainly used in retaining walls,bridge abutments,steep slope engineering,etc.Retaining walls and bridge abutments are load-bearing structures that withstand external loads such as active earth pressure,dynamic loads from the upper structure,and thermal stress.The reinforcement material is subjected to long-term tension and repeated dynamic loads,leading to fatigue in its molecular structure and performance degradation,which accelerates aging.To prevent significant deformation due to creep of the reinforcement material,unidirectional geogrids made from high-density polyethylene (HDPE) should be selected.Construction Methods:

○ When used for subgrades and road surfaces,the construction method is the same as for bidirectional geogrids.○ When used for reinforced soil retaining walls,the construction method is as follows:

Set up the foundation according to the designed wall system.When using precast reinforced concrete panels,they are typically 12–15 cm thick and supported on precast concrete foundations.The width should not exceed 30 cm,the thickness should be at least 20 cm,and the burial depth should be at least 60 cm to prevent frost heave effects.Level the wall base according to design requirements by excavating and leveling.Soft soil needs to be compacted or replaced,compacted to the required density,and slightly extended beyond the wall surface range.Lay the reinforcement material with the main strength direction perpendicular to the wall surface,fixed with pins.For wall backfilling,use mechanical filling,ensuring a distance of at least 15 cm between wheels and the reinforcement material.After compaction,each layer of soil should be about 20–15 cm thick.During wall surface construction,geotextile should be wrapped at the wall surface to prevent soil loss.

Product

Contact Us

Contact Person: Chen Fan

Phone: +8615666086733

Email: GangCaiDaWang@gmail.com

Address: Anlinzhan Industrial Park, Feicheng City, Tai'an City, Shandong Province

Product Display

Online Message