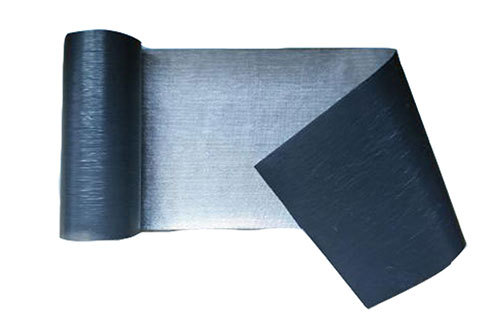

Physically damaged geotextile rolls must be repaired. Severely worn geotextiles are not permitted for use. Any geotextile exposed to leaking chemical reagents is not allowed for use in this project.

Geotextile Installation Methods:

Manual unrolling shall be used, ensuring the surface is flat with appropriate allowance for deformation.

Installation of filament or staple fiber geotextiles typically involves overlapping, sewing, or welding. Sewn or welded seams generally require a width of at least 0.1m, while overlapped seams require a width of at least 0.2m. Geotextiles that may be exposed for extended periods should be welded or sewn.

Sewing of geotextiles: All sewing must be continuous (e.g., spot stitching is not allowed). Before overlapping, a minimum overlap of 150mm is required. The minimum stitch distance from the selvedge (exposed edge of the material) should be at least 25mm. Sewn geotextile seams must include at least one row of lock-stitch chain stitching. The thread used for sewing should be resin-based with a minimum tensile strength of 60N, offering chemical resistance and UV resistance comparable to or greater than that of the geotextile. Any missed stitches in the sewn geotextile must be re-sewn in the affected areas. Measures must be taken to prevent soil, particulate matter, or foreign substances from entering the geotextile layer after installation. The overlapping of geotextile can be categorized based on topography and function into natural overlapping, sewing, or welding.

During construction, the geotextile above the geomembrane shall be naturally overlapped, while the geotextile on the upper layer of the geomembrane shall be sewn or hot-air welded. Hot-air welding is the preferred method for connecting filament geotextiles, where a hot-air gun is used to instantaneously heat the connection between two sheets to a partially molten state, followed immediately by the application of external force to ensure firm adhesion. Under潮湿 (rainy or snowy) conditions where thermal bonding is not feasible, sewing shall be used as an alternative connection method. This involves using a specialized sewing machine for double-thread stitching with chemical-resistant and UV-resistant thread.

Minimum width for sewing: 10cm

Minimum width for natural overlapping: 20cm

Minimum width for hot-air welding: 20cm

For sewing, thread of the same quality as the geotextile must be used, with superior resistance to chemical degradation and UV exposure.

After geotextile installation is completed and approved by the site supervision engineer, the geomembrane shall be installed.

The geotextile on the geomembrane shall be installed simultaneously after the geomembrane is approved by the Owner and Supervisor.

The respective layers of geotextile are labeled as TN and BN.

Both the upper and lower layers of geotextile at the anchoring trench locations must be embedded into the trench together with the geomembrane.

Basic Requirements for Geotextile Installation:

Seams must intersect with the slope line. In areas parallel to the toe of the slope or where stress may occur, the distance of horizontal seams must exceed 1.5m.

On slopes, one end of the geotextile must be anchored, and the roll shall be unrolled down the slope to ensure the geotextile remains taut.

All geotextiles must be weighted down with sandbags, which will be used during installation and remain until the next layer of material is installed.

Geotextile Installation Process Requirements:

Subgrade inspection: Check if the subgrade is level and firm. Remove any foreign objects and address issues appropriately.

Trial installation: Based on site conditions, determine the geotextile dimensions, cut accordingly, and conduct a trial installation. Cutting dimensions must be accurate.

Check if the overlapping width is appropriate. The overlapping area should be flat and moderately tight.

Positioning: Use a hot-air gun to bond the overlapping sections of two geotextile sheets. The spacing of bonding points should be suitable.

When sewing overlapping sections, the stitching thread should be straight, and stitches should be even.

After sewing, inspect the geotextile to ensure it is laid flat and free of defects.

If any non-compliant issues are found, repairs should be made promptly.

Self-Inspection and Repair of Geotextile Installation:

a. All geotextile sheets and seams must be inspected. Defective sheets and seams must be clearly marked on the geotextile and repaired.

b. Worn geotextile must be repaired by installing and thermally bonding small geotextile patches. Patches must extend at least 200mm beyond the defective edges in all directions. Thermal bonding must be strictly controlled to ensure the patch bonds firmly to the geotextile without causing damage.

c. At the end of each day's installation, visually inspect all installed geotextile surfaces to ensure all damaged areas are marked and repaired immediately. Confirm that the installation surface is free of foreign objects that could cause damage, such as fine needles or small nails.

d. The following technical requirements must be met when repairing damaged geotextile:

e. Patch material for holes or cracks must be identical to the geotextile.

f. Patches must extend at least 30cm beyond the damaged area of the geotextile.

g. At the bottom of the landfill, if the tear in the geotextile exceeds 10% of the roll width, the damaged section must be cut out, and the two geotextile sheets must be connected. On slopes, if the tear exceeds 10% of the roll width, the entire roll must be removed and replaced with a new one.

h. Footwear and tools used by construction personnel must not damage the geotextile. Personnel must not engage in any activities on installed geotextile that could cause harm, such as smoking or puncturing the geotextile with sharp tools.

i. To ensure the safety of the geotextile material, packaging film should be removed immediately before installation, i.e., unroll one roll at a time. Inspect the visual quality upon unrolling.

j. Special note: Geotextile delivered to the site must be accepted and quantified with signed certification in a timely manner. Strictly adhere to the company's "Geotextile Installation and Acceptance Specifications."

Product

Contact Us

Contact Person: Chen Fan

Phone: +8615666086733

Email: GangCaiDaWang@gmail.com

Address: Anlinzhan Industrial Park, Feicheng City, Tai'an City, Shandong Province

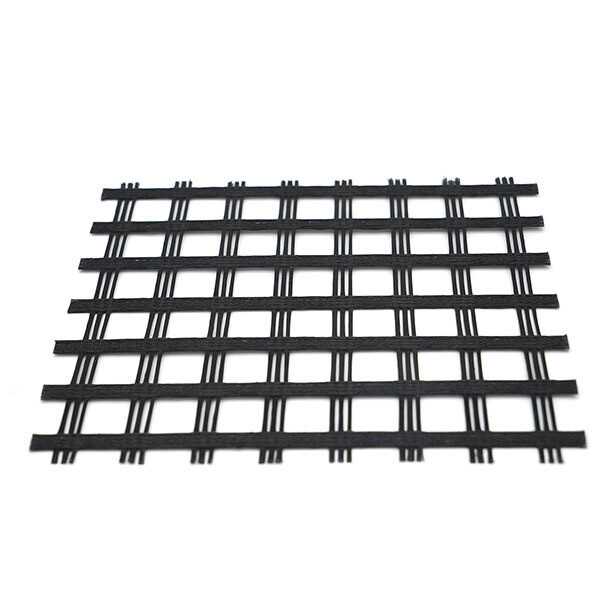

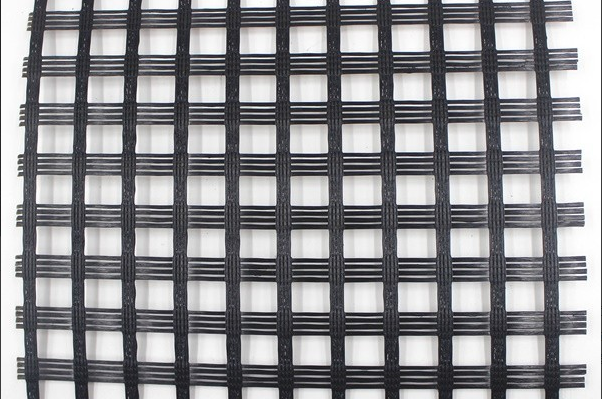

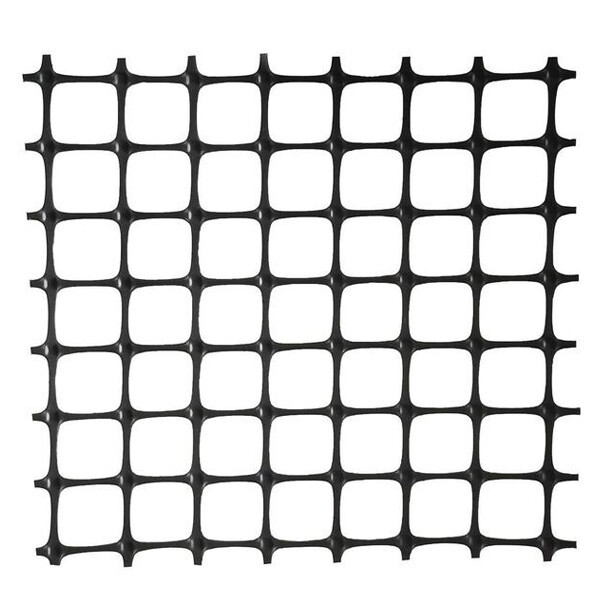

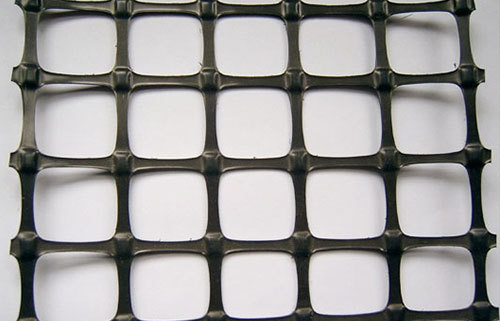

Product Display

Online Message