PRODUCT CENTER

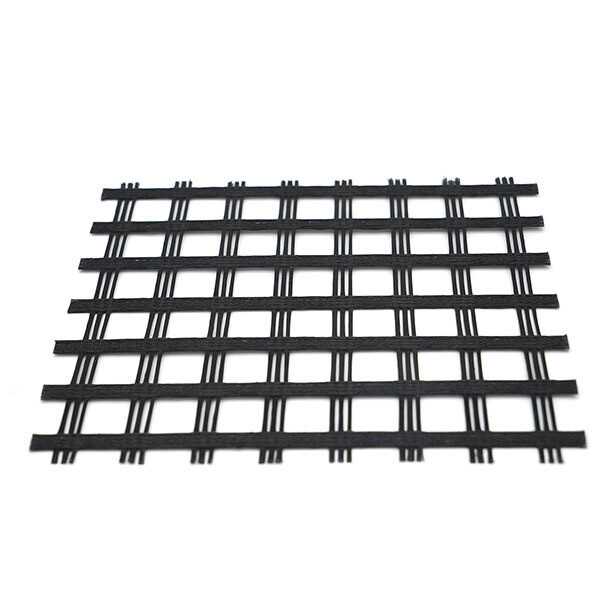

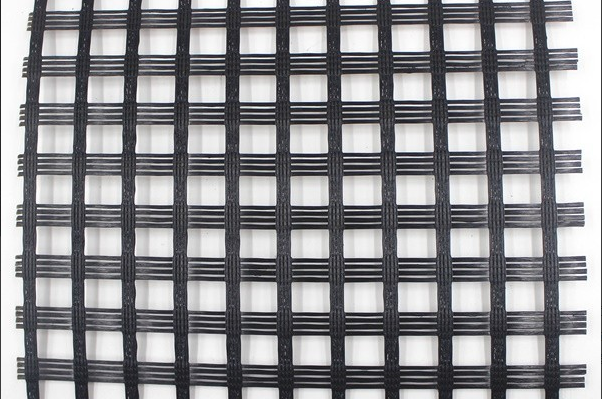

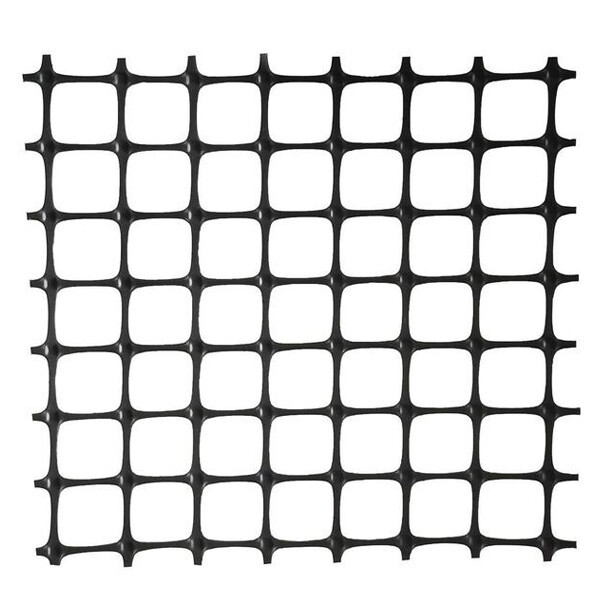

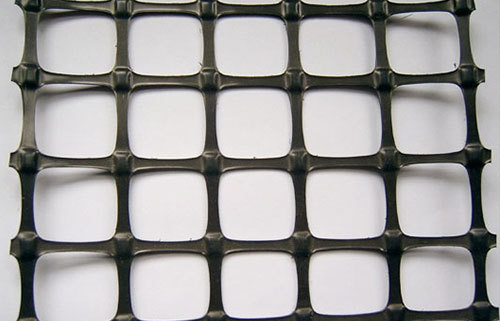

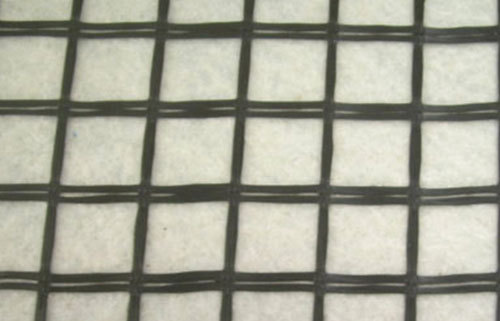

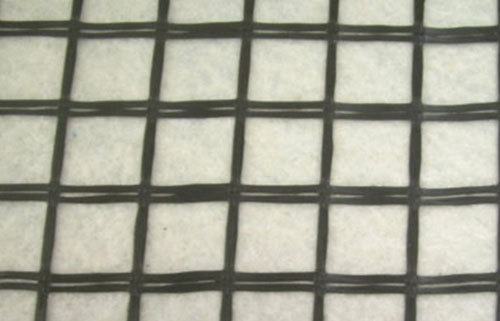

Uniaxial Stretched Plastic Geogrid:

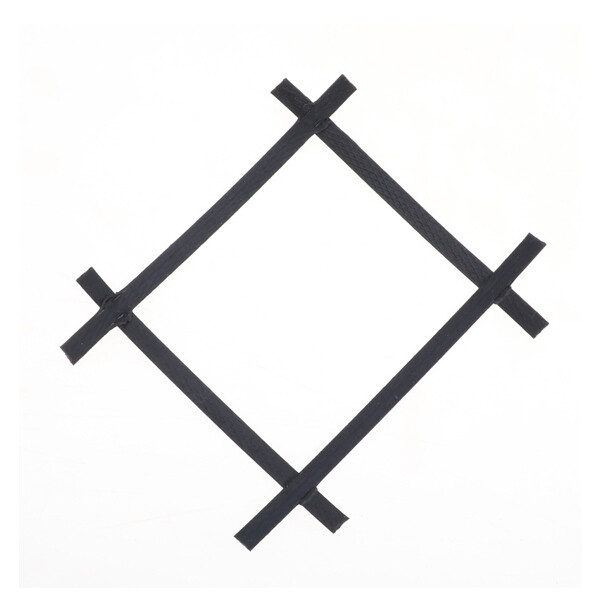

Polyethylene uniaxial stretched geogrid is made from high-density polyethylene (HDPE) as raw material,through plasticizing extrusion into sheets,punching,heating,and stretching. The stretching process realigns the originally dispersed chain molecules into a linear orientation,significantly enhancing the tensile strength and rigidity of the geogrid. When laid in soil,the interlocking and mutual restraint between the geogrid mesh and the soil form an efficient stress transfer mechanism. This allows local loads to be rapidly and effectively distributed over a large area of soil,thereby reducing local destructive stress and extending the service life of the project.

The outstanding advantage of polyethylene uniaxial stretched geogrid is its minimal tendency to deform (creep) under long-term sustained loads. Its anti-creep strength far surpasses that of geogrids made from other materials,playing a crucial role in extending the service life of projects.

This product is suitable for constructing reinforced retaining walls,embankments,bridge decks,steep slopes,and geocells in projects such as highways,railways,and river,lake,and coastal banks. Its function is to enhance the bearing capacity of retaining walls or embankments,extend their service life,reduce land occupation,shorten construction periods,lower costs,and minimize maintenance expenses.

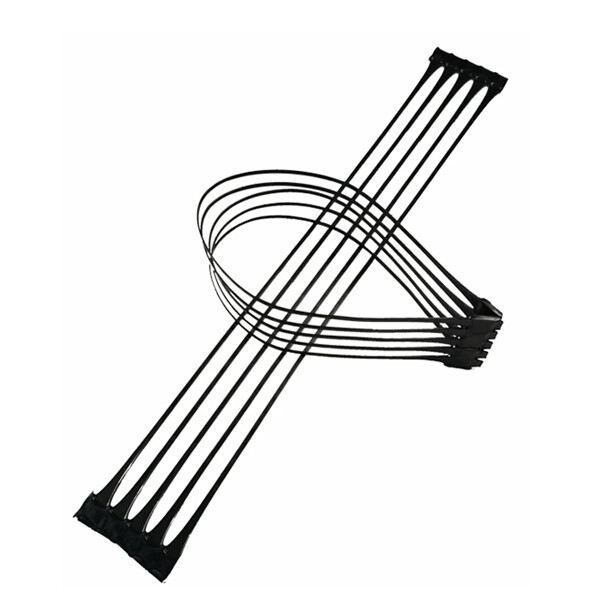

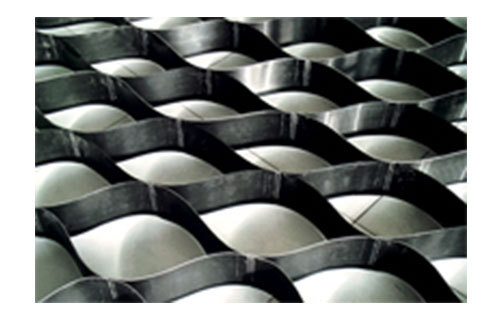

Uniaxial stretched geogrid is produced by extruding polymer into thin sheets,punching regular mesh holes,and then stretching them longitudinally. This process orients the polymer molecules into a linear state,forming a uniform and highly robust oval mesh structure with high node strength. This structure exhibits exceptionally high tensile strength and modulus,particularly in products from our company,which surpass international standards with high early-stage (elongation between 2% and 5%) tensile strength and modulus. It provides an ideal force-bearing and diffusion连锁 system for the soil. With high tensile strength (>150 MPa) and adaptability to various soil types,this product is widely used as a reinforcement material.

Applications:

Uniaxial stretched geogrid is a high-strength geosynthetic material widely used in embankments,tunnels,docks,highways,railways,construction,and other fields. Its main applications include:

Enhancing subgrades by effectively distributing and diffusing loads,improving the stability and bearing capacity of the subgrade,and extending its service life.

Withstanding greater alternating loads.

Preventing subgrade deformation and cracking caused by the loss of subgrade materials.

Increasing the self-bearing capacity of fill soil behind retaining walls,reducing earth pressure on the retaining walls,saving costs,extending service life,and reducing maintenance expenses.

Combining with shotcrete methods for slope maintenance,not only saving 30%–50% of investment but also shortening the construction period by more than half.

Incorporating geogrid into highway subgrades and surface layers can reduce deflection,minimize rutting,delay crack formation by 3–9 times,and reduce structural layer thickness by up to 36%.

Adaptability to various soil types without the need for importing materials,saving time and labor.

Simple and quick construction,significantly reducing construction costs.

Product

Contact Us

Contact Person: Chen Fan

Phone: +8615666086733

Email: GangCaiDaWang@gmail.com

Address: Anlinzhan Industrial Park, Feicheng City, Tai'an City, Shandong Province

Product Display

Online Message