PRODUCT CENTER

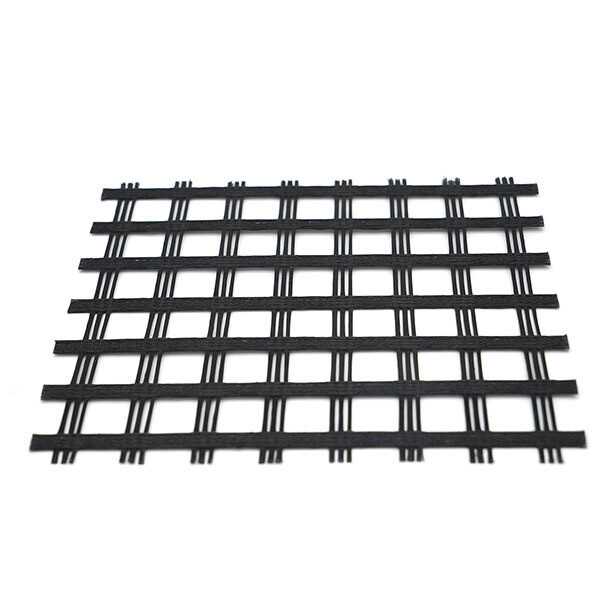

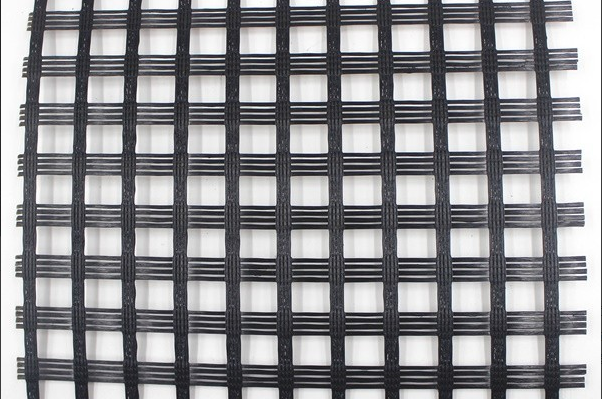

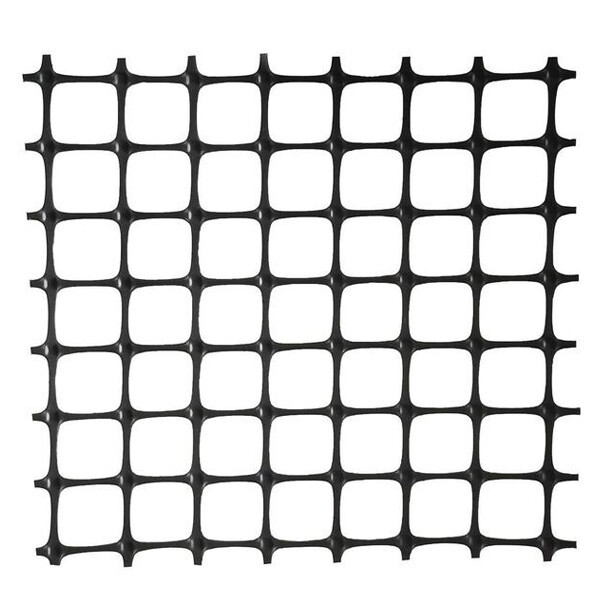

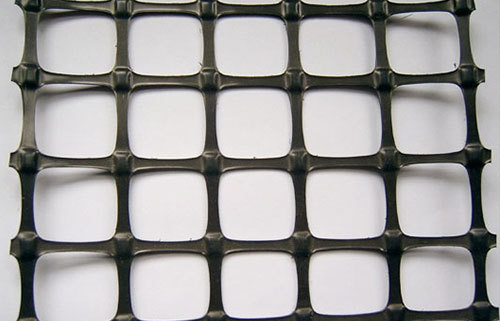

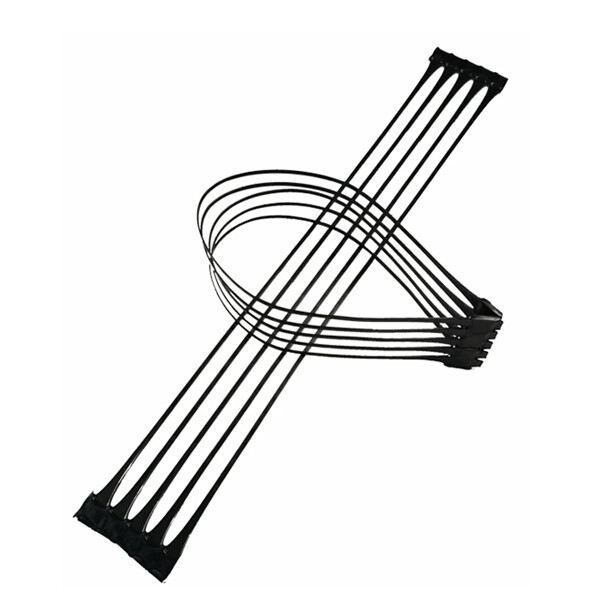

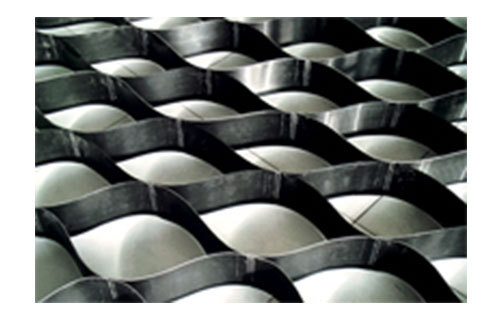

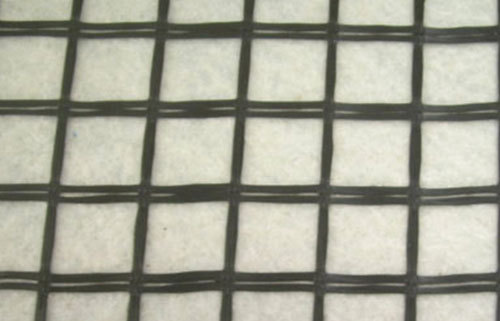

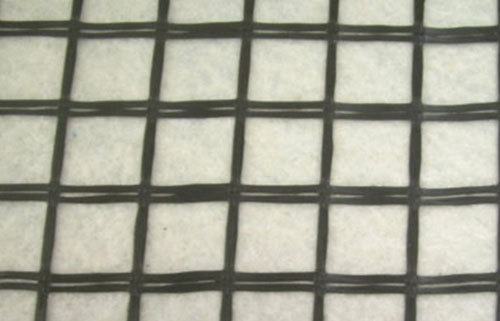

Performance Characteristics of Fiberglass Geogrid:

The product features high strength, low elongation, high temperature resistance, high modulus, light weight, good toughness, corrosion resistance, and long service life. It is widely used in old cement pavement rehabilitation, airport runway maintenance, embankments, riverbanks, slope protection, and road and bridge pavement reinforcement. It enhances and strengthens pavements, prevents rutting, fatigue cracks, thermal and cold shrinkage cracks, and underlying reflective cracks. It also disperses pavement stress, extends pavement service life, and offers high tensile strength, low elongation, no long-term creep, excellent physical and chemical stability, thermal stability, resistance to fatigue cracking, high-temperature rutting resistance, low-temperature shrinkage cracking resistance, and delayed reduction of reflective cracks.

Applications of Fiberglass Geogrid:

Reinforcement of old asphalt concrete pavements to enhance the asphalt surface layer and prevent diseases.

Transformation of cement concrete pavements into composite pavements to suppress reflective cracks caused by slab shrinkage.

Road expansion and renovation projects to prevent cracks caused by uneven settlement at the junction of old and new sections.

Reinforcement of soft soil foundations to facilitate water drainage and consolidation, effectively suppress settlement, evenly distribute stress, and enhance the overall strength of the subgrade.

Reinforcement of new road semi-rigid bases to prevent reflective cracks from base layer cracks causing pavement cracks.

Construction of Fiberglass Geogrid:

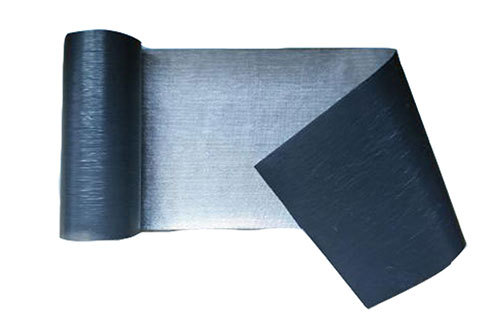

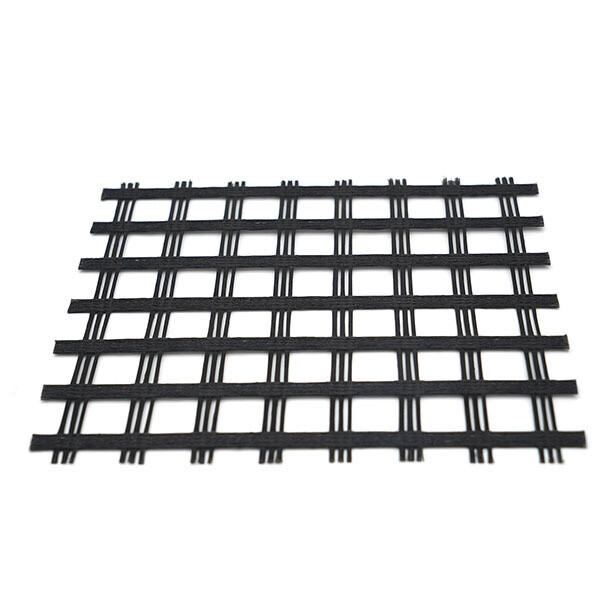

Common types of fiberglass geogrid include self-adhesive and non-self-adhesive varieties. Self-adhesive geogrid can be directly laid on a leveled base layer, while non-self-adhesive geogrid is typically fixed using nails.

Construction Method for Non-Self-Adhesive Fiberglass Geogrid:

Nail Fixation Method:

Fix one end of the geogrid to the underlying structure with tack coat asphalt using iron sheets and nails. Nails can be hammered or shot in with a nail gun.

Tighten the geogrid longitudinally and fix it in sections, each 2-5 meters long. For cement concrete pavements, section length can correspond to contraction joint spacing. Nails should be placed at joints, ensuring the geogrid is taut and straight both longitudinally and transversely.

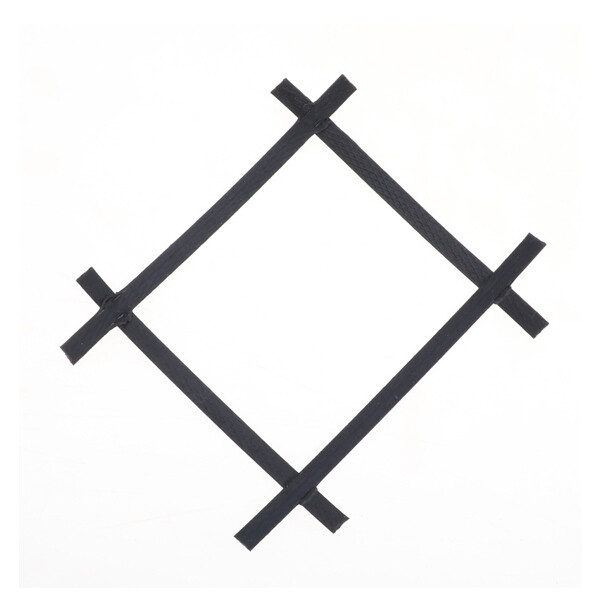

Geogrid Overlap:

Longitudinal overlaps should be at least 20 cm, and transverse overlaps should be at least 15 cm. Longitudinal overlaps should be oriented in the direction of asphalt paving, with the previous section overlapped by the subsequent one.

Precautions:

Do not nail directly into the geogrid or hammer it directly. If nails are broken or iron sheets are loose, re-fix them.

Compaction:

After laying and fixing, lightly compact the geogrid with a rubber-wheel roller to ensure adhesion to the original road surface. Strictly control vehicle access, and prohibit sharp turns, sudden braking, or dumping of mixed materials on the geogrid layer to avoid damage.

Construction Method for Self-Adhesive Fiberglass Geogrid:

Preparation:

Complete all joint filling, pit repair, base reinforcement, and leveling layer installation.

Road Surface Conditions:

The surface must be clean, dust-free, dry, and at a temperature between 5°C and 60°C.

Product Preparation:

Store self-adhesive fiberglass geogrid in a dry environment to maintain adhesiveness.

Precautions:

Workers must wear gloves when handling self-adhesive geogrid.

Cut the geogrid with a knife if it obstructs road markers or obstacles.

Avoid wrinkles during laying by applying sufficient tension.

Overlap ends by 75-150 mm in the direction of laying.

Overlap sides by 25-50 mm.

After laying and compaction, only construction or emergency vehicles are allowed, ensuring no damage from turning or braking.

Asphalt mixing and paving must be completed on the same day, with a minimum surface asphalt thickness of 40 mm.

Laying Methods:

Mechanical Laying:

Mount the geogrid roll on a dispenser in front of a tractor, adhesive side down.

Drive the tractor forward to ensure the geogrid lays flat and adheres to the road surface.

Compact lightly with a rubber-wheel roller 1-2 times.

Pave the asphalt mixture.

Manual Laying:

Place the geogrid roll on a dispenser on a truck or handcart, adhesive side down.

Ensure the dispenser axle is locked to prevent loosening.

Step on one end of the geogrid as the truck (or handcart) moves forward slowly. Adjust promptly to avoid wrinkles.

Compact lightly with a rubber-wheel roller 1-2 times to activate the adhesive, then pave the asphalt surface.

Product

Contact Us

Contact Person: Chen Fan

Phone: +8615666086733

Email: GangCaiDaWang@gmail.com

Address: Anlinzhan Industrial Park, Feicheng City, Tai'an City, Shandong Province

Product Display

Online Message